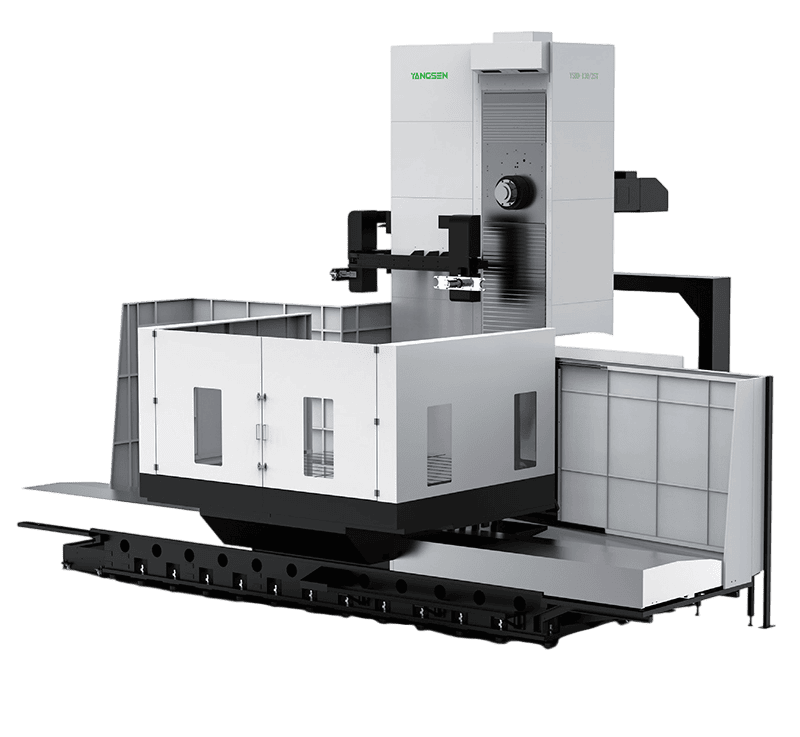

YSBD-160/20T हॉरिजॉन्टल बोरिंग मशीन को बड़े और भारी वर्कपीस की हेवी-ड्यूटी मशीनिंग के लिए डिज़ाइन किया गया है, जो असाधारण मजबूती, सटीकता और कटिंग स्थिरता प्रदान करती है। बड़ी क्षमता वाली वर्कटेबल से लैस यह हॉरिजॉन्टल बोरिंग मिलिंग मशीन भारी भार सहन कर सकती है, जिससे यह ऊर्जा, भारी उपकरण निर्माण, जहाज निर्माण और बड़े संरचनात्मक घटकों के उत्पादन जैसे उद्योगों के लिए आदर्श है।

मैक्स। एक्स-अक्ष यात्रा :

4000mmमैक्स। वाई-अक्ष यात्रा :

3000mmमैक्स। Z- अक्ष यात्रा :

1500mmमैक्स वर्कपीस की लंबाई :

2500mmमैक्स वर्कपीस चौड़ाई :

2500mmमैक्स वर्कपीस वजन :

54Tआवेदन :

Auto Partsप्रसंस्करण :

Surface Milling, Drilling Holes, Tappingक्षैतिज बोरिंग-मिलिंग मशीनिंग सेंटर संरचनात्मक विशेषताएँ

यह क्षैतिज बोरिंग मशीन इसमें एक सुसज्जित है उच्च-सटीकता वाला घूर्णनशील कार्य सारणी की विशेषता 4 × 90° टेपर पिन पोजिशनिंग के साथ संयुक्त स्वचालित हाइड्रोलिक लॉकिंगजिससे मल्टी-फेस मशीनिंग के दौरान सटीक स्थिति निर्धारण सुनिश्चित हो सके।

यह टेबल एक द्वारा संचालित है डिजिटल-नियंत्रित एसी सर्वो मोटर और एक सटीक वर्म गियर ट्रांसमिशन प्रणालीप्रभावी प्रदान करना प्रतिक्रिया क्षतिपूर्ति और सुचारू घूर्णी गति। बी-अक्ष के लिए, एक आयातित हाइड्रोलिक डिस्क-प्रकार क्लैम्पिंग प्रणाली इसे अपनाया गया है, जो असाधारण क्लैम्पिंग बल प्रदान करता है ताकि पूरी तरह से सहारा मिल सके। कठोर कटाई की स्थितियों में भारी-भरकम बोरिंग और मिलिंग संचालन.

क्षैतिज बोरिंग-मिलिंग मशीन की विशेषताएं:

उच्च कठोरता वाले ढलवां लोहे के मशीन बेड और स्तंभ

इस क्षैतिज बोरिंग मिलिंग मशीन के मुख्य संरचनात्मक घटक एचटी300 उच्च-शक्ति वाले कच्चे लोहे का उपयोग करके निर्मित किए जाते हैं, जो एल्यूमीनियम-लकड़ी के संयुक्त पैटर्न और राल रेत ढलाई प्रक्रिया के माध्यम से उत्पादित होते हैं।

सघन बेकिंग और तनाव-मुक्ति उपचार के बाद, ढलाई उत्कृष्ट कठोरता, कंपन अवशोषण और आयामी स्थिरता प्रदान करती है, जो उच्च परिशुद्धता और भारी भार वाली मशीनिंग के लिए एक ठोस आधार बनाती है। यह मजबूत संरचनात्मक डिज़ाइन मशीन के स्थायित्व को उल्लेखनीय रूप से बढ़ाती है और चुनौतीपूर्ण औद्योगिक अनुप्रयोगों में दीर्घकालिक सटीकता सुनिश्चित करती है।

कुशल चिप निष्कासन एवं तापीय नियंत्रण प्रणाली

मशीनिंग की दीर्घकालिक सटीकता बनाए रखने के लिए, मशीन संरचना को एक आरक्षित सर्पिल चिप कन्वेयर इंटरफ़ेस के साथ डिज़ाइन किया गया है, जो स्वचालित चिप निकासी प्रणाली के निर्बाध एकीकरण की अनुमति देता है।

उच्च दक्षता वाला कटिंग फ्लूइड फ्लशिंग उपकरण कटिंग ज़ोन से चिप्स को लगातार हटाता रहता है, जिससे चिप्स का जमाव रुकता है और मशीन की संरचना पर ऊष्मीय प्रभाव कम होता है। यह डिज़ाइन लंबे मशीनिंग चक्रों के दौरान स्थिर ऊष्मीय नियंत्रण, बेहतर सतह फिनिश और निरंतर परिशुद्धता सुनिश्चित करने में सहायक है।

पैरामीटर

| परियोजना | विनिर्देश | इकाई | वाईएसबीडी-160/20टी |

| यात्रा | X/Y/Z/W अक्ष | mm | 4000/3000/1500/700 |

| स्पिंडल नोज से वर्कटेबल तक | mm | 95-3095 | |

| स्पिंडल केंद्र से स्तंभ तक | mm | -25-2375 | |

| X/Y/Z गाइडवे | रोलर गाइड | ||

| काम की मेज | वर्कटेबल का आकार (लंबाई-चौड़ाई) | mm | 2500*2500 |

| अधिकतम टेबल भार | kg | 20000 | |

| टेबल स्क्रू | नहीं/मिमी | 0.001 | |

| धुरा | स्पिंडल प्रकार(मॉडल संख्या / माउंटिंग आकार) | mm | बीटी50 |

| स्पिंडल गति | आरपीएम | 3000 | |

| स्पिंडल ड्राइव प्रकार | गियर प्रकार | ||

| बोरिंग बार व्यास | mm | 160 | |

| फीड दर | तीव्र पारगमन (X/Y/Z) | मीटर/मिनट | 10/10/10/8 |

| कटाई फ़ीड दर (X/Y/Z) | मिमी/मिनट | 10/10/10/5 | |

| औजार परिवर्तक (विकल्प) | स्वचालित टूल चेंजर | ट्रैक प्रकार | |

| टूल शैंक का प्रकार | प्रकार | बीटी50 | |

| उपकरण भंडारण क्षमता | औजार | 40 | |

| अधिकतम उपकरण व्यास (आसन्न) | mm | 125 | |

| अधिकतम उपकरण व्यास (खाली) | mm | 250 | |

| अधिकतम उपकरण लंबाई | mm | 500 | |

| अधिकतम उपकरण भार | Kg | 25 | |

| सबसे कम समय में टूल बदलें | सेकंड | 14 | |

| मोटर | स्पिंडल मोटर | kw | एआईआईएल30/7000 |

| तीन-अक्षीय सर्वो मोटर | kw | AIF40/3000/AIF40B/3000/AIF40/3000/AIF22/3000 | |

| पानी काटने वाले पंप मोटर | एम/एचएम | 4-60 | |

| शुद्धता | X/Y/Z/W स्थिति सटीकता | mm | 0.015/0.012/0.01 |

| X/Y/Z/W में बार-बार स्थिति निर्धारण की सटीकता | mm | 0.008/0.0080.005 | |

| शक्ति आवश्यक | बिजली की आवश्यकता | केवीए | 95 |

| वायु दाब की आवश्यकता | किलोग्राम/सेमी | 6^8 | |

| अन्य | बाह्य आयाम (लंबाई/चौड़ाई/ऊंचाई) | mm | 9000*8800*6100 |

| कुल वजन | t | 54 |

मानक सहायक उपकरण

| एआरएम प्रकार टूल चेंजर | कठोर टैपिंग | डुअल एलईडी वर्क लाइट | Spनाक से हवा का फूँक |

| स्वचालित स्नेहन प्रणाली | इलेक्ट्रिक कैबिनेट के लिए ऊष्मा विनिमय | एलईडी 3 रंग की चेतावनी लाइट | लेवलिंग बोल्ट और पैड |

| सेमी-एंडोस्ड गार्ड | कूलेंट टैंक और चिप ट्रे | M30 ऑटो ऑफ | रोटरी टेबल |

विकल्प

| ऑप्टिकल रैखिक पैमाना | उपकरण टूटने प्रणाली | तेल धुंध संग्राहक | वर्कपीस और टूल प्रोब |

| सीटीएस | चिप कन्वेयर सिस्टम | तेल स्किमर | ऑटो पार्ट्स प्रोब मापन प्रणाली |

टैग :