कंप्यूटर न्यूमेरिकल कंट्रोल (सीएनसी) मशीनें आधुनिक विनिर्माण का आधार बन गई हैं, जो सटीक, स्वचालित और कुशल मशीनिंग प्रक्रियाओं को संभव बनाती हैं। इनका उपयोग ऑटोमोटिव, एयरोस्पेस, इलेक्ट्रॉनिक्स और सामान्य इंजीनियरिंग सहित विभिन्न उद्योगों में उच्च सटीकता और स्थिरता वाले पुर्जे बनाने के लिए किया जाता है।

विशिष्ट उत्पादन आवश्यकताओं के लिए उपयुक्त उपकरण चुनने हेतु विभिन्न प्रकार की सीएनसी मशीनों को समझना अत्यंत महत्वपूर्ण है। प्रत्येक श्रेणी—जैसे मिलिंग, टर्निंग, ड्रिलिंग, ग्राइंडिंग और कटिंग मशीनें—विशिष्ट उद्देश्यों की पूर्ति करती हैं और सटीकता, गति और सामग्री अनुकूलता के मामले में अद्वितीय लाभ प्रदान करती हैं।

सीएनसी मशीन (कंप्यूटर न्यूमेरिकल कंट्रोल मशीन) एक स्वचालित उपकरण है जो उच्च परिशुद्धता के साथ मशीनिंग संचालन को नियंत्रित करने के लिए कंप्यूटर प्रोग्रामिंग का उपयोग करता है। मशीनिस्ट द्वारा मैन्युअल रूप से संचालित होने के बजाय, सीएनसी प्रणाली कोडित निर्देशों का पालन करती है—जो अक्सर जी-कोड में लिखे होते हैं—ताकि कटिंग टूल्स या वर्कपीस को निर्धारित पथों पर चलाया जा सके।

सीएनसी मशीनों का व्यापक रूप से मिलिंग, टर्निंग, ड्रिलिंग और ग्राइंडिंग जैसे जटिल निर्माण कार्यों के लिए उपयोग किया जाता है, जिससे निर्माता असाधारण सटीकता, दोहराव और गति के साथ पुर्जे बना सकते हैं। प्रत्येक गति, उपकरण परिवर्तन और फीड दर स्वचालित रूप से नियंत्रित होती है, जिससे बड़े उत्पादन में निरंतर गुणवत्ता सुनिश्चित होती है।

सीएनसी मशीनिंग की अवधारणा पारंपरिक मैनुअल नियंत्रण प्रणालियों से 20वीं सदी के मध्य में विकसित हुई, जब धातु काटने को स्वचालित करने के लिए पहली बार छिद्रित टेप और संख्यात्मक कोड का उपयोग किया गया था। आज, सीएनसी तकनीक प्रक्रिया की स्थिरता और दक्षता बढ़ाने के लिए उन्नत नियंत्रण प्रणालियों, सेंसरों और यहाँ तक कि एआई को भी एकीकृत करती है।

आधुनिक कारखानों में, सीएनसी मशीनें केवल धातु काटने तक ही सीमित नहीं हैं। इनका उपयोग प्लास्टिक, कंपोजिट, सिरेमिक और लकड़ी पर भी किया जाता है, जिससे ये ऑटोमोटिव, एयरोस्पेस, चिकित्सा और इलेक्ट्रॉनिक्स निर्माण जैसे उद्योगों में अपरिहार्य हो जाती हैं।

संक्षेप में, सी.एन.सी. मशीनों ने निर्माताओं के सटीक इंजीनियरिंग के प्रति दृष्टिकोण को बदल दिया है - मानव शिल्प कौशल और डिजिटल स्वचालन के बीच की खाई को पाट दिया है।

सीएनसी मशीनें कई प्रकार की होती हैं, और प्रत्येक विशिष्ट मशीनिंग कार्यों और सामग्री आवश्यकताओं के लिए डिज़ाइन की जाती है। ये मशीनें संरचना, उपकरण विन्यास और उनके द्वारा की जाने वाली गति के प्रकार—रैखिक, घूर्णी, या दोनों के संयोजन—में भिन्न होती हैं। नीचे सबसे आम सीएनसी मशीनों के प्रकारों की एक विस्तृत सूची दी गई है, साथ ही उनके मुख्य कार्य और विशिष्ट अनुप्रयोग भी दिए गए हैं।

सीएनसी मशीन का प्रकार | मुख्य समारोह | सामान्य अनुप्रयोग |

सीएनसी मिलिंग मशीन | एकाधिक अक्षों (X, Y, Z) के साथ घूमते हुए काटने वाले औजारों का उपयोग करके सामग्री को हटाता है | मोल्ड, डाई, सटीक पुर्जे, धातु आवास |

सीएनसी टर्निंग मशीन (खराद) | वर्कपीस को घुमाता है जबकि एक स्थिर कटिंग टूल इसे आकार देता है | शाफ्ट, बुशिंग, फास्टनर, बेलनाकार भाग |

सीएनसी ड्रिलिंग मशीन | स्वचालित ड्रिल बिट्स का उपयोग करके सटीक गहराई और व्यास के छेद बनाता है | इंजन ब्लॉक, प्लेट और यांत्रिक घटक |

सीएनसी पीसने की मशीन | सतह परिष्करण और सटीक सहनशीलता के लिए अपघर्षक पहियों का उपयोग करता है | उपकरण तेज करना, सतह परिष्करण, असर घटक |

सीएनसी बोरिंग मशीन | उच्च सटीकता के साथ मौजूदा छिद्रों को बड़ा या समाप्त करता है | इंजन सिलेंडर, बड़ी कास्टिंग, भारी मशीनरी पार्ट्स |

सीएनसी प्लाज्मा कटिंग मशीन | उच्च तापमान वाले प्लाज़्मा आर्क का उपयोग करके विद्युत प्रवाहकीय सामग्रियों को काटता है | शीट धातु निर्माण, ऑटोमोटिव फ्रेम |

सीएनसी लेजर कटिंग मशीन | सटीक, उच्च गति वाली कटाई और उत्कीर्णन के लिए केंद्रित लेजर किरणों का उपयोग करता है | पतली धातु की चादरें, इलेक्ट्रॉनिक्स, साइनेज, बढ़िया घटक |

सीएनसी ईडीएम (इलेक्ट्रिकल डिस्चार्ज मशीन) | उपकरण और वर्कपीस के बीच विद्युत निर्वहन द्वारा सामग्री को हटाता है | कठोर सामग्री, साँचे, डाई, एयरोस्पेस घटक |

सीएनसी राउटर | घूर्णन उपकरणों का उपयोग करके नरम सामग्रियों को काटना और आकार देना | लकड़ी, प्लास्टिक, फोम, मिश्रित भाग |

सीएनसी उत्कीर्णन मशीन | विस्तृत उत्कीर्णन, अंकन और बारीक पैटर्न काटने के लिए उपयोग किया जाता है | आभूषण, मोल्ड मार्किंग, नेमप्लेट, लोगो |

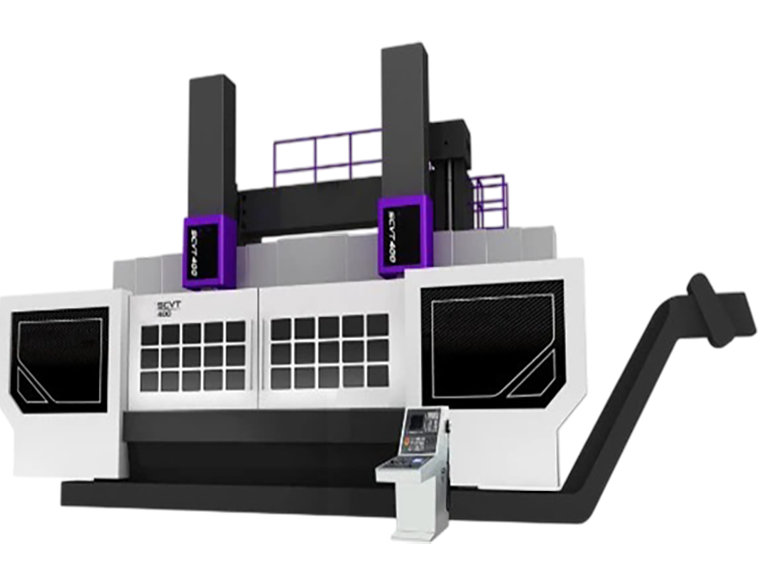

सीएनसी मशीनिंग केंद्र | मिलिंग, ड्रिलिंग, टैपिंग और टूल बदलने को संयोजित करने वाली एक बहुक्रियाशील प्रणाली | सटीक घटक, उच्च मात्रा में विनिर्माण |

5-अक्ष सीएनसी मशीन | जटिल ज्यामिति के लिए उन्नत बहु-दिशात्मक मशीनिंग प्रदान करता है | एयरोस्पेस, चिकित्सा प्रत्यारोपण, टरबाइन ब्लेड |

सीएनसी मशीनें साधारण 2-अक्ष मॉडल से लेकर जटिल 5-अक्ष या बहु-कार्य मशीनिंग केंद्रों तक हो सकती हैं जो एक ही सेटअप में टर्निंग और मिलिंग को एकीकृत करती हैं। सही प्रकार आवश्यक परिशुद्धता, सामग्री के प्रकार, उत्पादन मात्रा और भाग की जटिलता पर निर्भर करता है।

सभी सीएनसी मशीन प्रकारों में, सीएनसी मिलिंग मशीनों को सबसे बहुमुखी माना जाता है और आधुनिक विनिर्माण में व्यापक रूप से उपयोग किया जाता है। ये मशीनें एक स्थिर वर्कपीस से सामग्री को हटाने और उसे वांछित ज्यामिति में आकार देने के लिए कई अक्षों—आमतौर पर X, Y, और Z—पर कटिंग टूल्स को घुमाकर काम करती हैं।

सीएनसी मिलिंग मशीनों को मुख्य रूप से ऊर्ध्वाधर और क्षैतिज विन्यास में वर्गीकृत किया जाता है:

इनमें ऊर्ध्वाधर दिशा में स्थित स्पिंडल होते हैं। ये सटीक पुर्जों, सांचों और डाई-निर्माण के लिए आदर्श होते हैं, और उत्कृष्ट दृश्यता और सुगमता प्रदान करते हैं।

क्षैतिज मशीनिंग केंद्र (एचएमसी):

इसमें क्षैतिज रूप से स्थित स्पिंडल होता है, जिससे गुरुत्वाकर्षण-सहायता से चिप हटाने की सुविधा मिलती है तथा बड़े या भारी भागों की मशीनिंग में बेहतर दक्षता प्राप्त होती है।

उन्नत मॉडल, जैसे कि 5-अक्ष सीएनसी मिलिंग मशीन, अतिरिक्त घूर्णन गति प्रदान करते हैं, जिससे एक ही सेटअप में जटिल सतह मशीनिंग संभव हो जाती है। इससे सेटअप का समय कम होता है, सटीकता बढ़ती है, और यह एयरोस्पेस, चिकित्सा उपकरण निर्माण और उच्च-परिशुद्धता वाले मोल्ड निर्माण जैसे उद्योगों के लिए विशेष रूप से उपयोगी है।

सीएनसी मिलिंग मशीनों के प्रमुख प्रदर्शन कारकों में स्पिंडल गति, फ़ीड दर, यात्रा दूरी और उपकरण क्षमता शामिल हैं। आधुनिक प्रणालियाँ अक्सर स्वचालित उपकरण परिवर्तक (एटीसी) और उच्च गति वाले स्पिंडल से सुसज्जित होती हैं जो एक साथ कई उपकरणों के संचालन का समर्थन करते हैं।

सीएनसी टर्निंग मशीन, जिसे आमतौर पर कहा जाता है सीएनसी खराद, असाधारण सटीकता के साथ घूर्णन सममित भागों के उत्पादन के लिए डिज़ाइन किए गए हैं। मिलिंग मशीनों के विपरीत, जो स्थिर वर्कपीस के चारों ओर कटिंग टूल को घुमाती हैं, सीएनसी टर्निंग मशीनें वर्कपीस को घुमाती हैं जबकि स्थिर कटिंग टूल सामग्री को हटाता है। यह उन्हें शाफ्ट, बुशिंग, फास्टनरों और बेलनाकार घटकों के निर्माण के लिए आदर्श बनाता है जिनके लिए उच्च सतह परिष्करण और सख्त सहनशीलता की आवश्यकता होती है।

आधुनिक सीएनसी टर्निंग मशीनों को आमतौर पर नियंत्रित अक्षों की संख्या और उनकी मशीनिंग क्षमताओं के आधार पर वर्गीकृत किया जाता है:

2-अक्ष सीएनसी खराद:

ये मानक प्रकार हैं, जिनमें दो नियंत्रित अक्ष होते हैं - X और Z। ये उच्च दक्षता के साथ फेसिंग, टर्निंग, थ्रेडिंग और ग्रूविंग जैसे आवश्यक कार्य करते हैं।

3-अक्ष और सी-अक्ष खराद:

एक अतिरिक्त सी-अक्ष शामिल करें, जिससे बुनियादी मिलिंग, ड्रिलिंग और टैपिंग कार्यों के लिए स्पिंडल को अनुक्रमित या लगातार घुमाया जा सके।

बहु-अक्ष टर्निंग केंद्र (Y-अक्ष / उप-स्पिंडल):

एक ही सेटअप में जटिल, बहु-संचालन मशीनिंग के लिए डिज़ाइन किया गया, जिससे भाग को पुनः स्थापित करने और मैन्युअल हैंडलिंग की आवश्यकता कम हो जाती है।

स्विस-प्रकार सीएनसी खराद:

इसमें स्लाइडिंग हेडस्टॉक और गाइड बुशिंग प्रणाली है, जो चिकित्सा, इलेक्ट्रॉनिक्स और घड़ी निर्माण उद्योगों के लिए छोटे व्यास वाले भागों की अति-सटीक मशीनिंग की सुविधा प्रदान करती है।

उन्नत सीएनसी नियंत्रण प्रणालियों और स्वचालित टूल चेंजर्स से सुसज्जित, आधुनिक टर्निंग सेंटर उत्कृष्ट परिशुद्धता, गति और दोहराव प्रदान करते हैं। इनका व्यापक रूप से ऑटोमोटिव, एयरोस्पेस और हाइड्रोलिक निर्माण में उपयोग किया जाता है, जहाँ प्रदर्शन और स्थिरता महत्वपूर्ण होती है।

मिलिंग और टर्निंग के अलावा, सीएनसी ड्रिलिंग, बोरिंग और ग्राइंडिंग मशीनें सटीक छेद, बारीक सहनशीलता और उच्च-गुणवत्ता वाली सतह फिनिश प्राप्त करने में महत्वपूर्ण भूमिका निभाती हैं। प्रत्येक प्रकार मशीनिंग प्रक्रिया में एक विशिष्ट उद्देश्य पूरा करता है और संपूर्ण विनिर्माण समाधानों के लिए अपरिहार्य है।

सीएनसी ड्रिलिंग मशीनें नियंत्रित गहराई और व्यास के साथ सटीक छेद बनाने के लिए डिज़ाइन किए गए हैं। इनमें कई स्पिंडल या बुर्ज हेड लगे हो सकते हैं, जिससे एक साथ कई छेद किए जा सकते हैं। उन्नत मॉडल एक ही चक्र में टैपिंग, काउंटरसिंकिंग और रीमिंग ऑपरेशन को सपोर्ट करते हैं। इन मशीनों का इस्तेमाल आमतौर पर ऑटोमोटिव, एयरोस्पेस और मशीनरी कंपोनेंट उत्पादन में किया जाता है, जहाँ सटीक संरेखण और छेदों की एकरूपता ज़रूरी होती है।

बोरिंग मशीनों का उपयोग मौजूदा छिद्रों को अत्यधिक सटीकता के साथ बड़ा और परिष्कृत करने के लिए किया जाता है। सीएनसी बोरिंग केंद्र अक्सर इंजन ब्लॉक, मशीन बेस और भारी ढलाई जैसे बड़े वर्कपीस को संभालते हैं। विशेष रूप से, क्षैतिज बोरिंग मशीनें बेहतर स्थिरता प्रदान करती हैं और गहरे छिद्रों वाली मशीनिंग के लिए आदर्श हैं। उनके कंप्यूटर-नियंत्रित फीड और स्पिंडल मूवमेंट बड़े पैमाने पर उत्पादन में भी सटीक आयामी सहनशीलता सुनिश्चित करते हैं।

सीएनसी ग्राइंडिंग मशीनें बेहतरीन सतही फिनिश और सटीक आयामी सटीकता प्राप्त करने के लिए अपघर्षक पहियों का उपयोग करती हैं। विन्यास के आधार पर, ये सतही ग्राइंडिंग, बेलनाकार ग्राइंडिंग या आंतरिक ग्राइंडिंग कर सकती हैं। ये मशीनें औज़ारों, बेयरिंग, डाई और सटीक पुर्जों के उत्पादन के लिए आवश्यक हैं, जहाँ माइक्रोन-स्तर की सटीकता आवश्यक होती है।

सीएनसी ड्रिलिंग, बोरिंग और ग्राइंडिंग मशीनें मिलकर मशीनिंग पारिस्थितिकी तंत्र का एक महत्वपूर्ण हिस्सा बनती हैं - जो आधुनिक औद्योगिक विनिर्माण के लिए सटीकता, स्थिरता और उच्च गुणवत्ता वाली सतह अखंडता प्रदान करती हैं।

A 5-अक्ष सीएनसी मशीन सीएनसी मशीनिंग तकनीक का सबसे उन्नत रूप प्रस्तुत करता है। यह किसी उपकरण या पुर्जे को एक साथ पाँच अलग-अलग अक्षों पर गति प्रदान कर सकता है—पारंपरिक X, Y, और Z रैखिक अक्षों के साथ-साथ दो अतिरिक्त घूर्णन अक्षों (A और B) पर भी। यह विन्यास उपकरण को लगभग किसी भी दिशा से वर्कपीस तक पहुँचने की अनुमति देता है।

5-अक्षीय मशीनों का उपयोग जटिल ज्यामिति और उच्च-परिशुद्धता वाले घटकों के लिए किया जाता है, जैसे कि एयरोस्पेस, चिकित्सा और ऑटोमोटिव उद्योगों में। ये उन पुर्जों के लिए आदर्श हैं जिनके कई सतहों पर मशीनिंग की आवश्यकता होती है या जिनमें जटिल वक्र होते हैं जिनके लिए अन्यथा कई सेटअप की आवश्यकता होती है।

लाभ:

अत्यधिक जटिल और समोच्च सतहों का निर्माण करने में सक्षम

सेटअप समय कम करता है - एक ही बार में कई पक्षों पर मशीनिंग की जा सकती है

पुनर्स्थापन त्रुटियों को न्यूनतम करके सटीकता में सुधार करता है

उपकरण की चिकनी गति के कारण सतह की फिनिशिंग में सुधार होता है

सामान्य अनुप्रयोग:

टरबाइन ब्लेड और प्ररितक

एयरोस्पेस संरचनात्मक भागों

कृत्रिम जोड़ और चिकित्सा प्रत्यारोपण

उच्च-प्रदर्शन ऑटोमोटिव घटक

एक सीएनसी मशीन कई प्रमुख घटकों से बनी होती है जो सटीकता, गति और विश्वसनीयता सुनिश्चित करने के लिए एक साथ काम करते हैं। इन भागों को समझने से उपयोगकर्ताओं को अपनी मशीनों को अधिक प्रभावी ढंग से संचालित करने, रखरखाव करने और समस्या निवारण करने में मदद मिलती है।

सीएनसी नियंत्रक मशीन का "दिमाग" होता है। यह प्रोग्राम से प्राप्त जी-कोड निर्देशों की व्याख्या करता है और मोटरों और एक्चुएटर्स को सटीक आदेश भेजता है।

कार्य: प्रोग्राम इनपुट, समन्वय नियंत्रण और त्रुटि का पता लगाना

उदाहरण: फैनुक, सीमेंस, मित्सुबिशी, या हेडेनहाइन नियंत्रक

मशीन बेड सीएनसी मशीन की नींव का काम करता है। यह अन्य सभी घटकों को सहारा देता है और मशीनिंग के दौरान कंपन को अवशोषित करके सटीकता बनाए रखता है।

उच्च स्थिरता और कठोरता के लिए आमतौर पर कच्चा लोहा या खनिज मिश्रित सामग्री से बनाया जाता है।

स्पिंडल वह घूमने वाला घटक है जो काटने वाले औज़ार को पकड़कर चलाता है। इसका प्रदर्शन मशीनिंग की गति और सतह की फिनिश को सीधे प्रभावित करता है।

बेल्ट-चालित, गियर-चालित, या प्रत्यक्ष-ड्राइव (अंतर्निहित) प्रकार का हो सकता है।

एल्युमीनियम और मिश्रित सामग्रियों की सटीक मशीनिंग के लिए उच्च गति वाले स्पिंडल आवश्यक हैं।

स्वचालित उपकरण परिवर्तक (एटीसी) मशीन को विभिन्न काटने वाले उपकरणों के बीच स्वचालित रूप से स्विच करने में सक्षम बनाता है, जिससे दक्षता बढ़ती है और डाउनटाइम कम होता है।

सामान्य प्रकार: ड्रम-प्रकार और चेन-प्रकार उपकरण परिवर्तक।

विशिष्ट क्षमता: मशीन के आकार के आधार पर 16 से 60 उपकरण।

अक्ष ड्राइव प्रणाली प्रत्येक अक्ष (X, Y, Z, और अन्य) के साथ गति को नियंत्रित करती है।

बॉल स्क्रू और रैखिक गाइडवे सुचारू और सटीक स्थिति सुनिश्चित करते हैं।

सर्वो मोटर या स्टेपर मोटर फीडबैक नियंत्रण के साथ अक्षों को चलाते हैं।

कार्य-टेबल वह स्थान है जहां वर्कपीस को अक्सर फिक्सचर, वाइस या क्लैम्प का उपयोग करके स्थापित किया जाता है।

मशीन के प्रकार के आधार पर कई दिशाओं में घूम सकता है।

5-अक्ष मशीनों में, बहु-मुखीय मशीनिंग के लिए टेबल झुक सकती है या घूम सकती है

ये प्रणालियाँ तापमान स्थिरता बनाए रखती हैं और उपकरण को घिसने से बचाती हैं।

शीतलक काटने वाले क्षेत्र से गर्मी और चिप्स को हटा देता है।

स्नेहन यांत्रिक घटकों की सुचारू गति सुनिश्चित करता है।

एक सीएनसी मशीन, मशीनिंग प्रक्रिया को स्वचालित करने के लिए कम्प्यूटरीकृत निर्देशों का पालन करके काम करती है। यह प्रक्रिया एक डिजिटल डिज़ाइन से शुरू होती है, जो आमतौर पर CAD (कंप्यूटर-एडेड डिज़ाइन) सॉफ़्टवेयर में बनाया जाता है। फिर इस डिज़ाइन को G-कोड या M-कोड में बदल दिया जाता है, जो मशीन के निर्देशों के सेट के रूप में कार्य करता है।

चरण 1: प्रोग्रामिंग और सेटअप

ऑपरेटर भाग डिज़ाइन को सीएनसी नियंत्रक में लोड करता है।

सामग्री को क्लैंप, विज़ या फिक्सचर का उपयोग करके कार्य-टेबल पर स्थिर किया जाता है।

उपयुक्त काटने वाला उपकरण स्पिंडल या टूल बुर्ज में स्थापित किया जाता है।

चरण 2: मशीन गति

सीएनसी नियंत्रक मशीन के प्रत्येक अक्ष को नियंत्रित करने के लिए जी-कोड कमांड की व्याख्या करता है।

रैखिक अक्ष (X, Y, Z) उपकरण या कार्यवस्तु को सटीकता से चलाते हैं, जबकि घूर्णी अक्ष (A, B, C) बहु-अक्ष मशीनों में जटिल अभिविन्यास की अनुमति देते हैं।

सर्वो मोटर और बॉल स्क्रू सुचारू, सटीक और दोहराए जाने योग्य गति सुनिश्चित करते हैं।

चरण 3: सामग्री हटाना

काटने वाला उपकरण कार्यवस्तु को संलग्न करता है, तथा निर्धारित पथ के अनुसार सामग्री को हटाता है।

गुणवत्ता बनाए रखने और उपकरण को खराब होने से बचाने के लिए स्पिंडल की गति, फीड दर और कट की गहराई को स्वचालित रूप से नियंत्रित किया जाता है।

बहु-संचालन मशीनों के लिए, स्वचालित उपकरण परिवर्तक (एटीसी) प्रोग्राम को रोके बिना आवश्यकतानुसार उपकरणों को स्विच करता है।

चरण 4: निगरानी और प्रतिक्रिया

आधुनिक सी.एन.सी. मशीनों में स्पिंडल लोड, उपकरण घिसाव और अक्ष स्थिति की निगरानी के लिए सेंसर और फीडबैक सिस्टम होते हैं।

परिशुद्धता और दोहराव सुनिश्चित करने के लिए नियंत्रक वास्तविक समय में गतिविधियों को समायोजित करता है।

डिजिटल प्रोग्रामिंग, सटीक यांत्रिक गति और स्वचालित उपकरण संचालन के संयोजन से, सीएनसी मशीनें उच्च परिशुद्धता वाले घटकों का कुशलतापूर्वक, लगातार और न्यूनतम मानवीय हस्तक्षेप के साथ उत्पादन कर सकती हैं - जिससे वे आधुनिक विनिर्माण में अपरिहार्य हो जाती हैं।

सीएनसी मशीनें अपनी सटीकता, दक्षता और बहुमुखी प्रतिभा के कारण विभिन्न उद्योगों में व्यापक रूप से उपयोग की जाती हैं। उनके अनुप्रयोगों को समझने से निर्माताओं और इंजीनियरों को अपनी उत्पादन आवश्यकताओं के लिए सही मशीन प्रकार चुनने में मदद मिलती है।

1. एयरोस्पेस उद्योग

सीएनसी मशीनें टरबाइन ब्लेड, इंजन घटक और संरचनात्मक एयरफ्रेम भागों का उत्पादन करती हैं।

उच्च गति और बहु-अक्षीय सीएनसी मशीनिंग सुरक्षा-महत्वपूर्ण एयरोस्पेस घटकों के लिए आवश्यक सख्त सहनशीलता और जटिल ज्यामिति सुनिश्चित करती है।

2. ऑटोमोटिव उद्योग

आमतौर पर इंजन ब्लॉक, क्रैंकशाफ्ट, गियर और कस्टम वाहन भागों के लिए उपयोग किया जाता है।

सीएनसी मिलिंग और टर्निंग मशीनें बड़े पैमाने पर उत्पादन लाइनों में निरंतर गुणवत्ता बनाए रखते हुए उत्पादन की गति में सुधार करती हैं।

3. इलेक्ट्रॉनिक्स और विद्युत उपकरण

सीएनसी राउटर और छोटी मिलिंग मशीनों का उपयोग सर्किट बोर्ड, एल्यूमीनियम हाउसिंग और सटीक बाड़ों के लिए किया जाता है।

सीएनसी की उच्च सटीकता विश्वसनीय फिट और चिकनी फिनिश सुनिश्चित करती है, जो इलेक्ट्रॉनिक असेंबली के लिए आवश्यक है।

4. चिकित्सा और स्वास्थ्य सेवा

सीएनसी मशीनिंग प्रत्यारोपण, शल्य चिकित्सा उपकरणों और कृत्रिम घटकों के लिए महत्वपूर्ण है।

5-अक्ष या बहु-अक्ष क्षमता वाली मशीनें माइक्रोन स्तर की परिशुद्धता के साथ जटिल जैविक आकृतियां बना सकती हैं।

5. सामान्य विनिर्माण और टूलींग

सीएनसी मशीनें मोल्ड निर्माण, डाई उत्पादन और कस्टम यांत्रिक भागों का समर्थन करती हैं।

सतह पर घिसाई, ड्रिलिंग और मिलिंग क्षमताएं निर्माताओं को उच्च परिशुद्धता वाले उपकरण और घटकों का कुशलतापूर्वक उत्पादन करने की अनुमति देती हैं।

6. ऊर्जा और भारी मशीनरी

सीएनसी बोरिंग और टर्निंग मशीनें बड़ी कास्टिंग, टरबाइन घटकों और हाइड्रोलिक उपकरणों को संभालती हैं।

उच्च स्थिरता और स्वचालित नियंत्रण भारी-भरकम औद्योगिक भागों के लिए निरंतर सटीकता सुनिश्चित करते हैं।

सीएनसी मशीनों ने आधुनिक विनिर्माण को पूरी तरह से बदल दिया है, सटीकता, स्वचालन और बहुमुखी प्रतिभा प्रदान की है। मिलिंग और टर्निंग से लेकर ड्रिलिंग, ग्राइंडिंग और मल्टी-एक्सिस मशीनिंग तक, हर प्रकार की मशीन एयरोस्पेस, ऑटोमोटिव, इलेक्ट्रॉनिक्स और चिकित्सा जैसे उद्योगों में विशिष्ट उद्देश्यों की पूर्ति करती है।

सीएनसी मशीनों की सूची और उनके अनुप्रयोगों को समझने से निर्माताओं को अपनी उत्पादन आवश्यकताओं के लिए सही उपकरण चुनने में मदद मिलती है। एआई, आईओटी और स्वचालन में प्रगति के साथ, सीएनसी मशीनें अब उच्च दक्षता, सटीकता और जटिल पुर्जों की ज्यामिति को संभालने की क्षमता प्रदान करती हैं।

सही सीएनसी मशीन का चयन करके, निर्माता उत्पादकता में सुधार कर सकते हैं, गुणवत्ता बनाए रख सकते हैं और 2025 में प्रतिस्पर्धी बने रह सकते हैं।