किसी मशीन की दुकान में जाइए, और पहली चीज जो आपको ध्यान में आएगी, वह है मशीन की लगातार आती हुई ध्वनि। सीएनसी मशीनें काम पर। ये मशीनें स्टील, एल्युमीनियम और प्लास्टिक को इतनी सटीकता से काटती हैं जो हाथ से करना नामुमकिन है।

बहुत से लोग मानते हैं कि सारा जादू सॉफ्टवेयर में होता है। सच? मज़बूत और भरोसेमंद यांत्रिक पुर्जों के बिना, दुनिया का सबसे स्मार्ट प्रोग्राम भी एक भी काम नहीं कर पाएगा।

सीएनसी मशीन के यांत्रिक पुर्जे ही उसे चलाते रहते हैं क्योंकि वे हर कट को सहारा देते हैं, गति देते हैं और गति प्रदान करते हैं। वे भार संभालते हैं, सुचारू गति सुनिश्चित करते हैं, और हर पुर्जे को पूरी तरह से संरेखित रखते हैं।

जिस किसी ने भी दुकान में काम किया है, वह जानता है कि स्पिंडल में एक छोटी सी भी गड़बड़ी या एक स्क्रू का ढीला होना पूरे काम को बिगाड़ सकता है और दिन भर की मेहनत को बर्बाद कर सकता है। इसीलिए मशीनिस्ट और इंजीनियर अक्सर कहते हैं, "कोड पर भरोसा करने से पहले पुर्ज़ों पर भरोसा करो।"

इस ब्लॉग में, हम सीएनसी मशीनों के यांत्रिक पहलू पर विस्तार से नज़र डालेंगे। आप देखेंगे कि ये पुर्जे क्या हैं, ये एक साथ कैसे काम करते हैं, कौन से उद्योग इन पर निर्भर हैं, और सीएनसी तकनीक की दुनिया में आगे क्या होने वाला है।

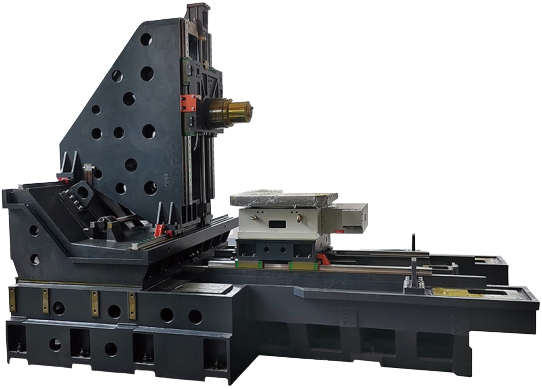

सीएनसी का मतलब है कंप्यूटर न्यूमेरिकल कंट्रोल। हालाँकि "कंप्यूटर" शब्द ध्यान खींचता है, लेकिन इसका यांत्रिक पहलू ही चीज़ों को वास्तविक बनाता है। जब आप किसी सीएनसी मशीन के पास जाते हैं, तो ये वो हिस्से होते हैं जिन्हें आप पकड़कर उनकी ओर इशारा कर सकते हैं।

मशीन का फ्रेम मोटा और मज़बूत है। यह सब कुछ स्थिर रखता है और उन कष्टप्रद कंपनों को रोकता है जो कट को बिगाड़ सकते हैं। स्क्रू और रेल उपकरण को सही दिशा में ले जाते हैं जहाँ उसे जाना है, जबकि स्पिंडल धातु को आकार देने के लिए घूमता है। और कूलिंग सिस्टम को भी न भूलें। यह चीज़ों को ज़्यादा गरम होने से बचाता है, खासकर लंबे, कठिन कामों के दौरान।

सीधे शब्दों में कहें तो, कंप्यूटर आदेश देता है, लेकिन ये पुर्जे ही मेहनत करते हैं, कोड को आपके सामने मौजूद सामग्री पर वास्तविक कट में बदलते हैं। इनमें से एक भी हिस्सा छूट जाए या नज़रअंदाज़ कर दिया जाए, तो मशीन ज़्यादा देर तक सटीक नहीं रहेगी।

प्रत्येक सीएनसी मशीन का निर्माण उसके उपयोग के आधार पर थोड़ा अलग तरीके से किया जाता है। लकड़ी के काम के लिए एक छोटा राउटर, एयरोस्पेस के लिए इस्तेमाल होने वाली भारी-भरकम मिलिंग मशीन जैसा नहीं होगा। फिर भी, कुछ घटक सामान्य होते हैं, और उनके बिना, किसी भी सीएनसी सिस्टम का संचालन संभव नहीं होगा। आइए उन पर चर्चा करें:

बेड सीएनसी मशीन के सबसे महत्वपूर्ण घटकों में से एक है।

●उद्देश्य: बेड को पूरी व्यवस्था का आधार मानें। इसका उद्देश्य काटने के दौरान होने वाले कंपन से होने वाले व्यवधान से बचने के लिए मशीन को स्थिर रखना है।

● सामग्री: कच्चा लोहा, स्टील, या अन्य मिश्रित सामग्रियाँ भारी भार के नीचे टिकने के लिए पर्याप्त मज़बूत होती हैं और बिस्तरों के लिए आमतौर पर इन्हीं का इस्तेमाल किया जाता है। ये कठोर और टिकाऊ होती हैं, और मुड़ने या हिलने पर भी अपना आकार बनाए रखती हैं।

स्पिंडल को अपने सीएनसी का मूल मानें। स्पिंडल कटिंग टूल को सहारा देता है और काम के अनुसार उसे अलग-अलग गति से घुमाता है। स्पिंडल के बिना कटिंग संभव नहीं है।

प्रकार:

● बेल्ट-चालित स्पिंडल: यह काफ़ी सस्ता और रखरखाव में आसान है। साथ ही, मध्यम गति वाले अनुप्रयोगों के लिए यह सबसे उपयुक्त है।

● डायरेक्ट-ड्राइव स्पिंडल: यह सीधे मोटर से जुड़ा होता है। इसलिए, यह और भी सुचारू और सटीक संचालन प्रदान करता है (बहुत तेज़ गति या बहुत सटीक कार्य के लिए आदर्श)।

● उच्च-स्तरीय स्पिंडल: इनमें से कुछ में मोटर और शीतलन प्रणालियां भी बनी होती हैं, जो लंबे, स्थिर और सटीक कट की अनुमति देती हैं।

विशेषताएँ: बड़ी क्षमता वाले बीयरिंग, भारी-भरकम आवास, तथा कुछ मामलों में, लम्बे समय तक उपयोग के लिए गर्मी को स्थानांतरित करने हेतु शीतलन जैकेट।

यह क्यों मायने रखती है: जब आपका स्पिंडल अपने सर्वोत्तम प्रदर्शन पर नहीं होता है, तो आपके पास कठोर सतह, स्क्रैप सामग्री और अधिक उपकरण घिसाव होगा।

ये वे तत्व हैं जो मशीन को सुचारू और सटीक यात्रा प्रदान करते हैं।

● बॉल स्क्रू: बॉल स्क्रू घूमने वाली गति को सीधी गति में बदल देते हैं। इन्हें सटीकता को माइक्रोन जितनी छोटी सीमा में बनाए रखने के लिए डिज़ाइन किया गया है।

● रैखिक गाइडवे: यह उपकरण ऐसे चलता है जैसे पटरी पर चल रहा हो। यह X, Y, और Z सभी दिशाओं में सीधा और सही दिशा में चलता है।

वे क्यों महत्वपूर्ण हैं: बॉल स्क्रू और गाइडवे के साथ, मशीन आसानी से चलती है, कट सटीक रहते हैं, और उपकरण लंबे समय तक चलते हैं।

ये मूलतः वे मांसपेशियां हैं जो आपकी सीएनसी मशीन में प्रत्येक गति को शक्ति प्रदान करती हैं।

● ड्राइव मोटर्स: इनका उपयोग तब किया जाता है जब प्रथम श्रेणी की परिशुद्धता की आवश्यकता होती है, और स्टेपर मोटर्स सरल कार्यों के लिए सबसे उपयुक्त हैं।

● कपलिंग और बेल्ट: ये मोटरों को स्क्रू से जोड़ते हैं और गति को स्थिर बनाए रखते हैं। जब ये फिसलते हैं, तो गति अस्थिर हो जाती है और कट में त्रुटियाँ दिखाई देती हैं।

● एनकोडर: छोटे लेकिन महत्वपूर्ण एनकोडर, काटने वाले उपकरण की स्थिति पर लगातार नज़र रखते हैं। असल में, एक जीपीएस आपके स्पिंडल का मार्गदर्शन करता है।

यह क्यों मायने रखती है: अधिकांश अनुप्रयोगों के लिए, एक मानक तीन-अक्षीय मशीन पर्याप्त होती है, लेकिन पांच-अक्षीय या अन्य परिष्कृत विन्यासों में, ये प्रणालियां हाथ से भाग को रोके/रीसेट किए बिना जटिल, जटिल कटौती करने में सक्षम बनाती हैं।

सीएनसी मशीनें अक्सर एक ही उपकरण से संचालित नहीं होतीं।

● टूल होल्डर: ये कटिंग टूल को स्पिंडल में लॉक कर देते हैं ताकि मशीनिंग के दौरान यह स्थिर रहे। अगर होल्डर मज़बूत नहीं है, तो आपको चट-चट की आवाज़ सुनाई देगी, खुरदरी फिनिश दिखाई देगी, और शायद पुर्ज़ा भी खराब हो जाएगा।

● उपकरण परिवर्तक: स्वचालित उपकरण परिवर्तक, जिन्हें अक्सर ए.टी.सी. कहा जाता है, मशीन को कुछ ही सेकंड में नया उपकरण प्राप्त करने की सुविधा देते हैं, बिना किसी को हाथ से बदलने का इंतजार किए।

यह क्यों मायने रखती है: एयरोस्पेस पार्ट्स जैसे कामों में, एक कंपोनेंट के लिए बीस या उससे ज़्यादा उपकरणों की ज़रूरत पड़ना आम बात है। एटीसी के बिना, आपको बार-बार रुकना पड़ेगा, जिससे समय की बर्बादी होगी और उत्पादन की गति धीमी हो जाएगी।

उचित वर्कहोल्डिंग के बिना, आप केवल हवा काट रहे हैं।

● कार्य तालिकाएँ: कच्चे माल के लिए एक समतल आधार प्रदान करें।

● फिक्स्चर: अद्वितीय आकृतियों के लिए डिज़ाइन किए गए कस्टम सेटअप।

● वाइस और चक्स: हिलने से रोकने के लिए सामग्री को कसकर जकड़ें।

यह क्यों मायने रखती है: ढीले सेटअप के कारण चटख आवाज़, त्रुटियाँ या खराब पुर्ज़े हो सकते हैं। मज़बूत वर्कहोल्डिंग के साथ हर बार साफ़ और सटीक कट बनाए जाते हैं।

सीएनसी उपकरण संकेंद्रित ऊष्मा उत्पन्न करते हैं। बिना शीतलन के, उपकरण कुछ ही सेकंड में जल जाएँगे।

● शीतलक प्रणालियाँ: गर्मी को दूर करने और चिप्स को धोने के लिए काटने वाले उपकरण पर तरल पदार्थ या धुंध का छिड़काव करें।

● स्नेहन: चलने वाले पुर्जों को अच्छी स्थिति में रखना ज़रूरी है। इससे बॉल स्क्रू और गाइडवे घिसने से बच जाते हैं। अगर आप इसे नज़रअंदाज़ करेंगे, तो आपको चरमराहट सुनाई देने लगेगी। आपको कठोरता और सटीकता में कमी भी दिखाई दे सकती है।

फ़ायदे: अपनी मशीन को लुब्रिकेट करने से उसे सुचारू रूप से चलाने में मदद मिलती है। इससे आपके उपकरण लंबे समय तक चलते हैं। साथ ही, यह आपके तैयार पुर्जों को साफ़-सुथरा बनाए रखता है। नियमित रूप से लुब्रिकेट करने से आप बाद में महंगी मरम्मत से बच सकते हैं।

एक पुर्जा अकेले बहुत कुछ नहीं कर सकता। टीमवर्क ही सीएनसी मशीनों को खास बनाता है।

● फ्रेम सब कुछ स्थिर रखता है

● तकला काटने का काम करता है

● बॉल स्क्रू और गाइडवेज़ भागों को सटीकता से हिलाते हैं

● मोटरें उस गति को शक्ति प्रदान करती हैं

● मोटरें उस गति को चलाती हैं

● उपकरण परिवर्तक और धारक बिना किसी रुकावट के उत्पादन को बनाए रखते हैं।

बड़ी तस्वीर: सीएनसी मशीन के हर हिस्से को अपना काम करना ज़रूरी है। अगर आप किसी छोटी-सी बात, जैसे खराब लुब्रिकेशन या ढीले गाइडवे, को नज़रअंदाज़ कर देते हैं, तो सब कुछ गड़बड़ा सकता है। मशीन को अच्छी स्थिति में रखने से यह अच्छी तरह चलती है। इससे समय और पैसे की बचत होती है। साथ ही, इससे निराशा भी नहीं बढ़ती।

सीएनसी मशीनें हर जगह मौजूद हैं। कुछ उद्योग इनका इस्तेमाल छोटे पुर्जों के लिए करते हैं, तो कुछ बड़े ढाँचों के लिए। यहाँ कुछ ऐसे क्षेत्र दिए गए हैं जहाँ सीएनसी मशीन के यांत्रिक पुर्जे महत्वपूर्ण भूमिका निभाते हैं:

विमान के पुर्जों के लिए इतनी सख्त सहनशीलता की ज़रूरत होती है कि इंसान का बाल भी बहुत मोटा हो जाता है। कठोर फ्रेम और सटीक गाइडवे वाली सीएनसी मशीनें टर्बाइन ब्लेड, इंजन हाउसिंग और ऐसे संरचनात्मक पुर्जे बनाती हैं जिन्हें चरम स्थितियों में भी टिके रहना ज़रूरी होता है।

रक्षा अनुप्रयोगों में मिसाइल घटक, रडार आवास और सैन्य वाहन भाग शामिल हैं।

सीएनसी मशीनें छोटे-छोटे आवरण, कनेक्टर और सर्किट बोर्ड के पुर्जे बनाती हैं जहाँ मिलीमीटर की सटीकता मायने रखती है। चिकित्सा जगत में, लोग इनका इस्तेमाल इम्प्लांट, कृत्रिम अंग और सर्जरी के उपकरण बनाने में करते हैं। डॉक्टर और मरीज़ हर दिन इन उपकरणों पर निर्भर रहते हैं।

यहां, स्पिंडल और गाइडवे को माइक्रोमीटर परिशुद्धता के साथ काम करना चाहिए क्योंकि छोटी सी भी त्रुटि रोगी की सुरक्षा को खतरे में डाल सकती है।

सीएनसी मशीनें ऑटोमोटिव दुकानों में भारी सामान उठाने का काम संभालती हैं, इंजन ब्लॉक, गियर पार्ट्स और यहां तक कि वाहनों को सुरक्षित रखने वाले फ्रेम भी बनाती हैं।

खनन, निर्माण और ऊर्जा क्षेत्रों में, उन्हें और भी ज़्यादा मेहनत करनी पड़ती है और टाइटेनियम, कठोर स्टील और अन्य कठोर सामग्रियों को काटना पड़ता है। इस कार्यभार को झेलने के लिए, मशीनों को मज़बूत ढाँचों और कच्ची शक्ति के लिए बने स्पिंडल की ज़रूरत होती है।

पुर्जों का चयन बजट से कहीं अधिक महत्वपूर्ण है। यह फिट होने के बारे में है।

●स्पिंडल गति: स्पिंडल को अपनी सामग्री से मिलाएँ। एल्युमीनियम को उच्च RPM की आवश्यकता होती है। स्टील को धीमी, मज़बूत कटाई पसंद होती है। कंपोजिट कहीं बीच में आते हैं।

● कार्यधारण: आप अपने पुर्ज़े को कैसे सुरक्षित रखते हैं, यह सटीकता निर्धारित करता है। छोटे, सरल कामों के लिए मानक क्लैंप का उपयोग किया जा सकता है, जबकि मुश्किल पुर्ज़ों के लिए अक्सर कस्टम फिक्स्चर की आवश्यकता होती है।

● बिस्तर और फ्रेम की ताकत: जितना भारी और सख़्त होगा, उतना ही बेहतर होगा। एक अस्थिर फ़्रेम सटीकता को ख़त्म कर देता है।

● शीतलन प्रणालियाँ: लंबे समय तक चलने के लिए, उपकरणों को तेज रखने और भागों को साफ रखने के लिए विश्वसनीय शीतलन में निवेश करें।

● उपकरण परिवर्तक: यदि आपके काम में कई चरण शामिल हैं, तो स्वचालित उपकरण परिवर्तक हर पैसे के लायक हैं।

● स्वर्णिम नियम: ऐसी मशीन चुनें जो अभी आपके काम आए, लेकिन भविष्य को भी ध्यान में रखें। आज थोड़ा सा अपग्रेड आपको कल महंगे रिप्लेसमेंट से बचा सकता है।

सीएनसी मशीनों की नियमित रूप से सर्विसिंग करवानी पड़ती है। जल्दी में होने पर इसकी अनदेखी करने से महंगी देरी हो सकती है।

● स्नेहन: बॉल स्क्रू, बेयरिंग और गाइडवे को नियमित रूप से तेल या ग्रीस की ज़रूरत होती है। इससे उन्हें आसानी से फिसलने में मदद मिलती है। इससे वे अच्छी स्थिति में बने रहते हैं।

● संरेखण: ज़्यादा इस्तेमाल से पुर्जे हिल सकते हैं। अगर कट असमान दिखने लगें, तो अपने गाइडवे और अक्ष संरेखण की जाँच करें।

● स्पिंडल मुद्दे: अजीब आवाज़ों पर ध्यान दें। घिसने का मतलब अक्सर यह होता है कि बियरिंग खराब हो रही है। इसे जल्दी पकड़ने से पैसे बचते हैं।

● प्रतिक्रिया: घिसे हुए बॉल स्क्रू गति और उपकरण की प्रतिक्रिया में देरी का कारण बन सकते हैं। इसका मतलब है कि कट खराब होगा।

● शीतलक रिसाव: अगर लीकेज पर ध्यान न दिया जाए, तो इससे इलेक्ट्रॉनिक उपकरण खराब हो सकते हैं या पंप जाम हो सकते हैं। नियमित जाँच से आप छोटी-छोटी समस्याओं को बड़ी समस्या बनने से पहले ही पकड़ सकते हैं।

● निवारक देखभाल: थोड़ा सा नियमित रखरखाव बहुत मददगार साबित हो सकता है। इसे बनाए रखने से हजारों रुपये के मरम्मत बिल और उत्पादन समय की हानि से बचा जा सकता है।

सीएनसी उद्योग तेज़ी से बदल रहा है, और इन मशीनों को चलाने वाले पुर्जे भी बदल रहे हैं। आगे क्या होने वाला है, इसकी एक झलक यहाँ दी गई है:

● संकर सामग्री: मशीन फ्रेम में हल्के किन्तु मजबूत कंपोजिट का प्रयोग होने लगा है।

● बुद्धिमान स्पिंडल: कुछ स्पिंडलों में सेंसर लगे होते हैं जो गर्मी, कंपन और घिसाव पर नजर रखते हैं तथा खराबी से पहले आपको सूचित कर देते हैं।

● स्वचालित फिक्सचरिंग: कुछ नए क्लैंप और वर्कटेबल्स अलग-अलग आकार धारण करने के लिए अनुकूलित हो सकते हैं, जिससे सेटअप समय कम हो जाता है और त्रुटियों की संभावना कम हो जाती है।

● हरित शीतलन: नई शीतलन प्रणालियां तरल पदार्थों का पुनर्चक्रण करती हैं, अपशिष्ट को कम करती हैं, तथा प्रायः जैवनिम्नीकरणीय तरल पदार्थों का उपयोग करती हैं, जिससे उपकरण तेज रहते हैं तथा पर्यावरणीय प्रभाव कम होता है।

● एआई एकीकरण: कुछ मशीनों में उपकरण पथ और गति को स्वचालित रूप से संशोधित करने के लिए वास्तविक समय फीडबैक शामिल करना शुरू कर दिया गया है, जिससे काटने की गति तेज और अधिक सटीक हो जाती है।

भविष्य ऐसी सी.एन.सी. मशीनों की ओर अग्रसर है जो अधिक हरित, स्मार्ट और तीव्र होंगी।

एक सीएनसी मशीन मोटरों, स्टील और तारों का एक उलझा हुआ सा दिखता है। हालाँकि, कारखाने में समय बिताएँ, और आपको और भी बहुत कुछ दिखाई देगा। यांत्रिक पुर्जे ही मशीन को जीवंत बनाते हैं।

बेड सब कुछ स्थिर रखता है, स्पिंडल कट के माध्यम से शक्ति प्रदान करता है, बॉल स्क्रू और गाइडवे गति को सटीक रखते हैं, और शीतलन प्रणाली गर्मी से चीजों को गिरने से रोकती है।

जब ये सभी घटक ठीक से स्थापित और रखरखाव योग्य हों, तो सॉफ़्टवेयर त्रुटिहीन आउटपुट दे सकता है। इन्हें नज़रअंदाज़ करें, तो बेहतरीन प्रोग्राम भी कोई कमी नहीं छोड़ पाएगा।

चाहे आप एक मशीनिस्ट हों जो सख्त सहनशीलता की तलाश में हैं, एक खरीदार जो अगली मशीन खरीद रहा है, या एक शिक्षा प्राप्त करने वाला नौसिखिया, हार्डवेयर की जानकारी सर्वोपरि है। सही यांत्रिकी ही उत्पादन को साल-दर-साल सुचारू और सुसंगत बनाए रखने में सक्षम बनाती है।